Occupational safety and health

We consider it necessary to provide excellent buildings and construction services for "customer satisfaction." These "excellent buildings and construction services" are comprehensive, containing not only the meaning of being fundamental to the philosophy of our company, such as safe construction and securing quality, but also the meaning of making advanced efforts in consideration of social challenges. The entire company, including head/branch offices and field offices, is working together on "providing excellent buildings and construction services" so that we can respond sincerely and emphatically to the requests by society.

Policy/view

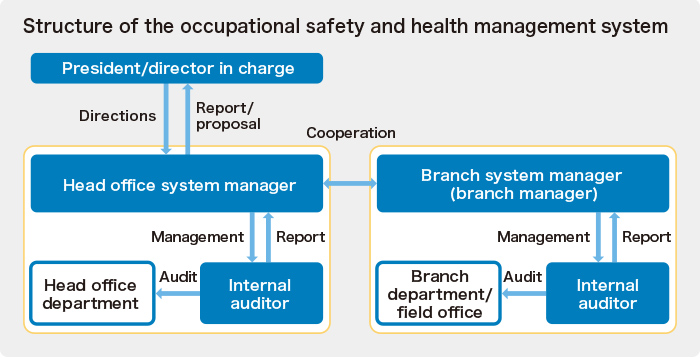

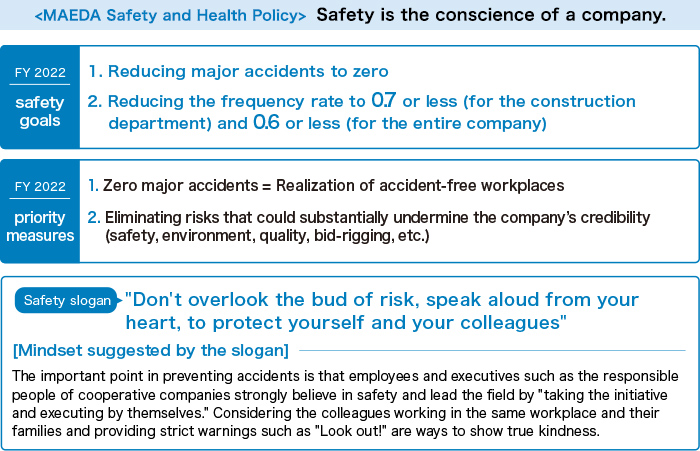

Reviewing major accidents in the past, our company established the "MAEDA Safety and Health Policy" as the basic concept of health and safety. With the fundamental principle that "Safety is the conscience of a company," the entire company performs accident prevention activities and makes efforts to create a safe workplace and a comfortable work environment. Furthermore, to prevent accidents, increase health, and create a comfortable workplace, we introduced the "Occupational Health and Safety Management System (OHSMS)" in 2001, in which we have established/maintained activities with risk assessment as a pillar to continuously improve the level of health and safety.

Management

We establish annual safety goals and priority measures as daily safety management activities and are promoting accident prevention activities. In addition, to establish a safety slogan, the head office, branch offices, field offices, the safety cooperation association, the supervisor association, and skilled workers are working together on the mutual heeding of unsafe actions. They are making efforts to create a work environment where accidents can be prevented beforehand.

Result

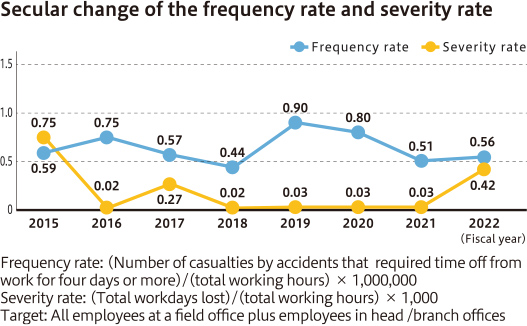

The safety performance of our company in FY2022 was as follows. The number of accidents resulting in absence from work was 37, among which 17 accidents resulted in four or more days of absence from work, and the frequency rate was 0.56.

Unfortunately, two fatal accidents are included in the above accidents, and we are making company-wide efforts to prevent the recurrence of accidents.

With the objective of "Zero major accidents" <Realization of accident-free workplaces>, we will continue to conduct various measures in FY 2023.

![Efforts for safety in the field: [KPI] safety performance](/assets/images/english/csr/sqp/ohas/ohas_img05.jpg)

Efforts to prevent accidents

To prevent similar accidents, we focus on the utilization and improvement of safety devices that cover human errors, the dissemination of work procedures, and the effective application of improved results to others by utilizing ICT. We also concentrate on education and make efforts to realize a safe work environment.

In the event that a major accident should occur, the responsible department manager and safety department manager of head/branch offices and field offices investigate the accident together, consider and conduct measures to prevent a recurrence, and change the internal rules and dispatch notifications when necessary. In such a way, the entire company is making efforts to prevent similar accidents in a unified fashion.

Implementation of a year-end priority patrol

The top management visits major construction sites throughout Japan and conducts safety patrols at the end of the year when occupational accidents are most likely to occur. On December 14, 2022, President Maeda visited Kajigaya Shield Workshop (Tokyo Civil Engineering Works Branch) where the latest excavation control system has been introduced. He cautioned the workers, “the recent trend of accidents shows that danger lurks in unstable works such as preparatory and clearance works. Preparatory or clearance work must be conducted in the same way as the main work. An unscheduled work that suddenly occurs may also lead to an accident. It is important to fully communicate with a cooperating company without leaving the work to them.” Furthermore, he called for an “active challenge” on safety measures because “making an investment in safety has the effect of increasing productivity.”

Implementation of a safety convention

Matching the preparation month prior to National Safety Week, a safety convention is held for each branch office around Japan jointly with the safety cooperation association. The top management always attends safety conventions, dispatching a message for safety to the employees of our company and the members of the safety cooperation association. Our company and the safety cooperation association have pledged to work on zero accidents and zero disasters unitedly.

Activities of the MAEDA rescue team

Our company is the only construction company to have a rescue team. It was inaugurated in 2007, based on the strong belief that "We should never allow such an event to happen again" without ever forgetting those unfortunate accidents that have occurred in the past. At present, periodic training is performed twice a year. On December 10 and 11, 2022, the executives and regular employees of head/branch offices and 30 team members including the captain conducted the 29th training at the tunnel site in a district of the Kansai Branch.

(Scenes of the 30th training)

Implementation of a joint patrol with the safety cooperation association

The safety cooperation association holds a safe environment subcommittee periodically, conducting activities such as the formulation of the action policy for health and safety. In addition, our company and the safety cooperation association (Zenyu-kai) jointly conduct the “joint safety patrol.”

In 2023, the safety cooperation association and the parties involved in safety including the officers in charge of safety at the head office of Maeda Corporation conducted the joint safety patrol at Tosu City Hall Workshop of the Kyushu Branch on November 10 and at the Tokyo Electric Generation Company's Miyadaira Hydropower Plant Workshop of Tokyo Civil Engineering Works Branch on December 9.

Development and introduction of a new technology for preventing traffic accidents in the construction industry, AI-based Hazardous Traffic Event Detection System (AI SAVE)

In a construction work in which soil and other materials are transported by dump trucks using ordinary roads and expressways, special consideration is required for the prevention of traffic accidents and safety measures.

Conventional vehicle-installed acceleration sensors and drive recorders have an issue that they cannot specifically alert drivers because their criteria of hazardous events are ambiguous.

Our company and Create-C Corporation jointly developed the “AI SAVE®” which is a system for analyzing images taken ahead of the transport vehicle (dump truck) using AI and allowing detected hazardous driving behaviors to be examined in detail and shared.

We introduced this system at the Futaba Interim Storage Facility Workshop and Haneda Land Development Workshop to promote the prevention of traffic accidents.

Setting March 21 as “MAEDA Safety Day,” we set up a “Showroom for Major Disasters That We Must not Forget” at the ICI camp.

The showroom displays panels entitled: “Contents of past disasters such as large-scale accidents occurring at the middle reach of the Mogami River, Oshimizu Tunnel, and Grimm Forest,” “Our efforts based on lessons learned from these disasters (formation of MRT, improvement of work safety through utilization of ICT technology),” and “Our vow for the safety of young employees during education for each generation.”

By making use of this showroom for employee education and training, we will pass down the experience of past major disasters to the future generation, encourage all employees to share our safety mindset to prevent similar disasters from occurring again, and seek to familiarize all employees again with our basic philosophy of “site control that gives priority to safety in all processes.”

Training on safety

* You can check the whole by scrolling horizontally.

| Name of training | Number of participants |

|---|---|

|

Training for new employees (orientation) |

105 |

|

Basic safety training in the third year |

98 |

|

Practical safety training in the fifth year |

105 |

Efforts by the Health and Safety Committee

The safety and health committee consisting of an industrial physician, a health supervisor, and health committee members (employees) is held once a month, in which the result of workplace patrol and measures taken based on the result and the state of long-hours of overtime are regularly reported, the information about the events required by law, such as promotion of regular medical checkups and guidance on implementation of stress check, is shared, and the committee members discuss how the health of employees can be supported, the workplace environment is improved, etc. while obtaining advice from the industrial physician and health supervisor.

We also promote the maintenance and enhancement of employees' health by reducing their disease risk. Focusing on mental health according to the “mental health promotion plan,” we are making various efforts such as the implementation of line-care and self-care training and setting and expansion of external consulting service desks. Since 2021, to reduce disease risk, public health nurses and nurses have conducted the promotion of health examination, complete medical checkup, and re-examination or detailed examination and the follow-up of people who are on leave. In addition, the consulting service desks for employees have also been playing an important role.

In FY2022, the public health nurse belonging to the head office took part in the health committee of each branch online and explained about the duties and roles of a public health nurse. As a result, the recognition degree of nurses and public health nurses is gradually increasing, and they have been increasingly receiving various consultations about mental health issues of employees as well as their subordinates or co-workers, questions about health examination results, etc.

We plan to continuously promote not only employees' health and safety, but also health management measures through all the safety and health committees in the company.

◆Efforts on COVID-19◆

COVID-19 was reclassified into Class 5 on May 8, 2023. Accordingly, the COVID-19 sick leave and the leave system for side reactions of the vaccine, which had been introduced as temporary legislations, were abolished, and the restrictions on face-to-face meetings and business trips and the obligation to wear a mask were also lifted.

However, at Maeda Corporation, we have been continuing ventilation of offices and the workplaces have been equipped with alcohol gel or the like, which many employees are using. Also, wiping desks with alcohol after work has already become a habit. We consider that certain activities to control infectious diseases have permeated through our employees.